Meeting the growing demand for cold storage solutions

26 Jun 2024

The cold storage industry is witnessing remarkable growth fueled by shifting consumer preferences and tightening regulations. With the global cold storage market reaching an estimated value of USD 119.8 billion in 2022 and projected to maintain a robust compound annual growth rate (CAGR) of 17.5% from 2023 to 2030, it's evident that this sector is gaining momentum.

Refrigerated storage has become integral to supply chains when storing and transporting temperature-sensitive products. In addition, the growing perishable product trade is also expected to boost the demand for refrigerated storage solutions over the next few years.

The modern economy requires cold storage solutions

The cold storage industry is not without its challenges, but it remains resilient and strong. High initial investments and operational costs are significant hurdles, but they are outweighed by the industry's strengths. Evolving consumer preferences, regulatory imperatives and technological advancements are driving the industry forward. The sector's potential for further growth and innovation in meeting the escalating demand for temperature-sensitive storage solutions is underscored by incentives like the IRA, which presents cost reduction and sustainability opportunities.

As this industry grows, many of Great River Energy’s member-owner cooperatives are working to support new and expanding cold storage warehouse projects in their service areas. One of the latest projects to be constructed in Minnesota is the Central Minnesota Cold Storage Facility in Wright-Hennepin Cooperative Electric Association’s service area in Clearwater, Minnesota.

Wright-Hennepin Cooperative Electric Association exemplifies how local member-owned cooperatives can support the growth of the cold storage industry while reducing its environmental impact. WH maintains several ongoing initiatives aimed at managing energy use and promoting sustainability:

- Renewable Energy: WH adds solar and wind power to its portfolio to reduce carbon emissions and enhance sustainability.

- Energy Efficiency: WH offers rebates for energy-efficient upgrades, smart management systems and energy audits to identify areas of improvement.

- Demand Response: WH incentivizes reduced electricity use during peak times, lowering costs and stabilizing the grid.

- Grid Modernization: WH invests in advanced metering infrastructure and automation to meet evolving energy needs with better efficiency and reliability.

- Collaborative Partnerships: WH collaborates with stakeholders to create and implement innovative energy solutions, promoting sustainable practices and positive environmental impacts to provide the greatest value for its member cooperatives.

WH is committed to being a valued partner to Minnesota Cold Storage, just as it is to its members, demonstrating its dedication to supporting the industry's growth while promoting environmental stewardship.

Challenges and opportunities

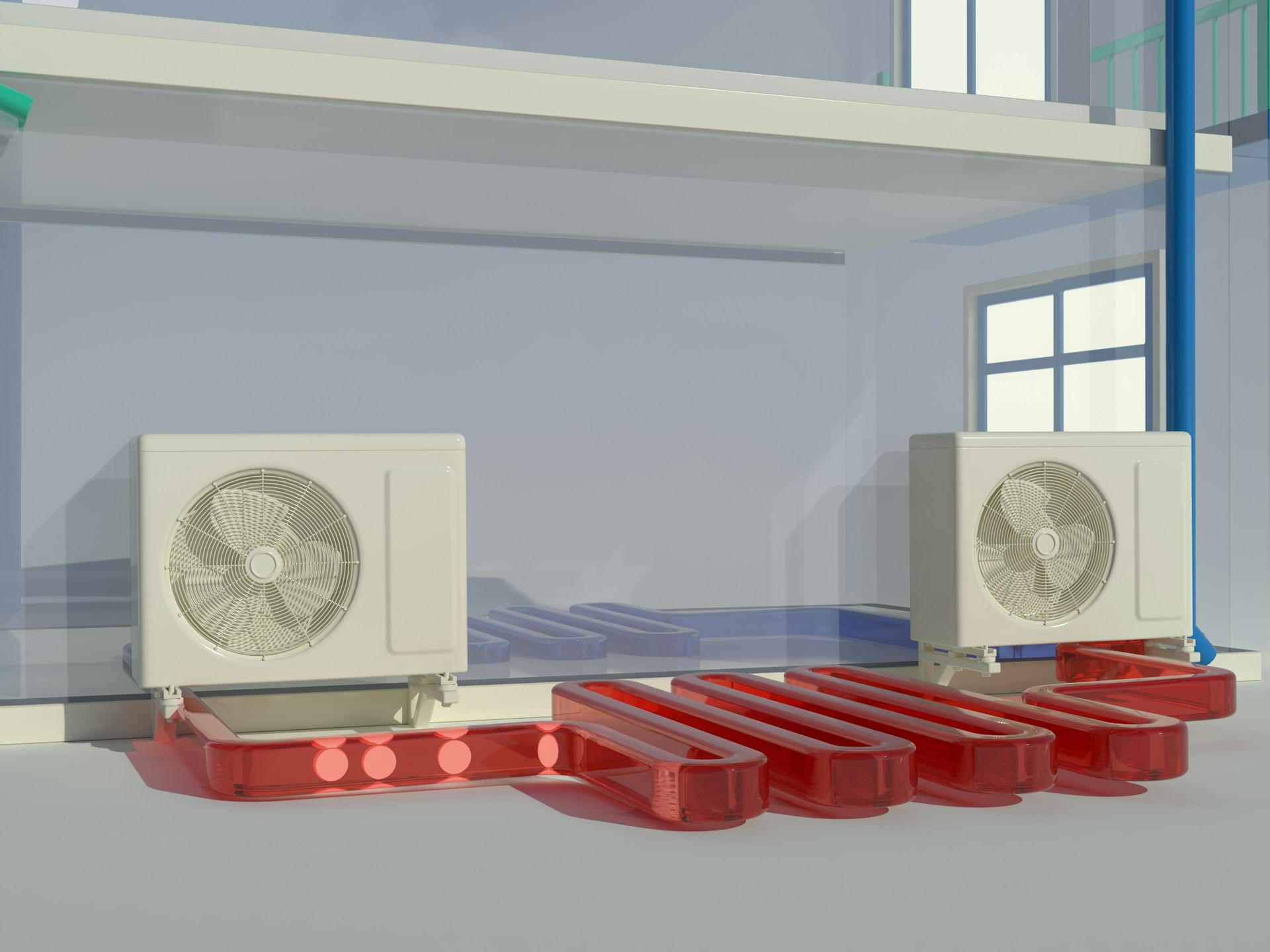

Constructing cold storage facilities entails substantial upfront infrastructure, equipment and maintenance investments. These costs present a notable barrier to entry for new market players, who must prioritize quality infrastructure and energy-efficient refrigeration systems to ensure product integrity and operational sustainability.

Energy consumption is a significant operational cost for cold storage facilities. Wright-Hennepin Cooperative Electric Association (WH), a member cooperative of Great River Energy, is actively addressing these challenges. WH invests heavily in technology to help its members manage their energy consumption effectively, thereby minimizing energy costs and maximizing long-term business sustainability.

One such initiative is implementing a new automated meter infrastructure (AMI) system. This system provides members with hourly energy usage readings, allowing them to benchmark how operational changes impact their energy usage and costs. This data-driven approach empowers members to make informed decisions about energy efficiency.

Furthermore, WH's Business Account representatives are partnering with commercial and industrial members to identify opportunities for energy efficiency improvements. These can include upgrading to LED lighting or installing variable frequency drives on motors, both of which can significantly reduce overall energy consumption.

In addition to these measures, cold storage operators can leverage incentives such as those provided by the Inflation Reduction Act (IRA) to address rising energy costs and promote environmental stewardship. This initiative allocates federal incentives for carbon emissions reduction and renewable energy projects, offering tax credits and grants to offset the costs of implementing energy-saving measures. By investing in solar energy, cold storage facilities can significantly reduce operational expenses, align with sustainable practices and enhance market competitiveness.

Constructing cold storage facilities entails substantial upfront infrastructure, equipment and maintenance investments. This challenge presents a notable barrier to entry for new market players, who must prioritize quality infrastructure and energy-efficient refrigeration systems to ensure product integrity and operational sustainability.

Cold storage operators can leverage incentives such as the Inflation Reduction Act (IRA) to address rising energy costs and promote environmental stewardship. This initiative allocates federal incentives for carbon emissions reduction and renewable energy projects and offers tax credits and grants to offset the costs of implementing energy-saving measures. By investing in solar energy, cold storage facilities can significantly reduce operational expenses and align with sustainable practices, enhancing market competitiveness.

Segmentation and market insights

According to data from the United States Department of Agriculture, public warehouses accounted for approximately 71% of the total refrigerated storage capacity in the U.S. as of October 2021. Operating as independent entities, public warehouses offer a fee for various services, including transportation, storage and handling.

The market can be segmented into facilities/services and equipment. Currently, the facilities and services segment dominates the market, capturing 89.8% of the revenue share in 2022. This segment, which includes refrigerated warehouses and cold rooms, is expected to sustain its growth momentum with a compound annual growth rate (CAGR) of 17.5% from 2023 to 2030.

On the other hand, the equipment segment is anticipated to exhibit the fastest growth, with a projected CAGR of 19.3% during the same period. The rising demand for frozen food, driven by evolving food preferences and the surge in online food delivery services, is a crucial factor propelling the growth of cold storage equipment. These systems play a vital role in preserving perishable goods, thus reducing food wastage and extending shelf life.

In addition to increased demand for fresh and frozen foods, the American Society of Health System Pharmacists (ASHP) reports that 43% of the new drugs approved by the FDA from January 2018 to March 2023 required cold storage, and 6% must be kept frozen. According to ASHP, “These high-cost drugs carry a significant risk of financial loss when subjected to unmitigated temperature excursions.”

Automation and its impact

Automation is a game-changer in the cold storage industry. Its integration within refrigerated warehouses is set to drive demand even higher. Cloud computing, conveyor systems, robotics and energy management solutions are real advancements revolutionizing cold storage operations. These technologies optimize efficiency and ensure the safe storage and transportation of temperature-sensitive goods, making refrigerated storage an indispensable part of modern supply chains.

Regulatory compliance and innovation

Stringent regulations governing the storage and transportation of temperature-sensitive products have emerged as significant drivers for market expansion. Compliance with these regulations necessitates precise temperature control throughout the supply chain, spurring the adoption of advanced refrigerated storage solutions. Furthermore, automation technologies such as cloud-based systems, robotics and energy management tools enhance operational efficiency and regulatory compliance within refrigerated warehouses.

Staying ahead: Great River Energy's commitment to innovation in cold storage development

Great River Energy acknowledges the vital role its member-owner cooperatives play in fostering the growth of the cold storage industry. In 2023, its team actively participated in key industry events, including the Global Cold Chain Alliance and the Controlled Environment Builders Association (CEBA).

By attending events like the CEBA Annual Conference & Expo, Great River Energy remains abreast of cutting-edge advancements in automation technologies and emissions reduction strategies, which are crucial for the continued development of cold storage facilities. While innovative technology and efficient electricity usage are exciting aspects of expanding cold storage facilities in Minnesota, the most rewarding aspect is the jobs and opportunities they create for local communities.

More Topics